October 29, 2024

3 min learn

This Sponge Captures the Teeny Bits of Gold in Digital Waste

A self-building sponge that effectively collects gold may eradicate some harsh strategies used to course of e-waste

If all 62 million metric tons of digital waste produced in a yr have been loaded into rubbish vans, they’d encircle the planet bumper to bumper, based on a latest United Nations report. And hidden in that monstrous visitors jam can be startling quantities of valuable metals, together with gold—essential in electronics as a result of it conducts electrical energy, stretches into wires and gained’t simply corrode. Fashionable iPhones have gold of their cameras, circuit boards and USB-C connector. Pound for pound, there’s extra gold in cell telephones than in ore from a typical gold mine.

However wringing valuable metals from trashed electronics is a harsh enterprise. Utilizing energy-intensive smelters, recycling amenities course of e-waste with punishing warmth. Or they’ll use caustic brokers to interrupt down bulk electronics into liquids filled with steel ions, an strategy that then requires complicated electrochemical processes and poisonous therapies to extract precious parts of their metallic kinds. The seek for environmentally friendlier strategies that skip these extra steps has led supplies scientists down some uncommon alleyways: For example, an aerogel constituted of whey protein—a cheese by-product—can seize gold ions from pc motherboards bathed in acid. One other experimental materials, described this month within the Proceedings of the Nationwide Academy of Sciences USA, combines graphene (a one-atom-thick sheet of carbon) with chitosan, a sugar present in shrimp shells. As a result of chitosan spontaneously attaches to the carbon sheet, the sponge basically builds itself.

Of their preliminary experiments, the research authors used the sponge to filter water that contained gold ions. The pale yellow liquid turned clear as gold particles piled up on the graphene’s floor. As soon as there, the ions reacted with chitosan, a pure decreasing agent that helped remodel the gold again into its metallic kind. The researchers additionally examined the sponge on partially processed e-waste; when the scientists elevated the liquid’s acidity to a pH of three, the chitosan within the sponge captured the remaining gold whereas ignoring different metals. Though it requires an acidic setting, the sponge may eradicate the necessity for additional processing, which may depend on poisons reminiscent of cyanide to acquire metallic gold from liquids. “Our method allows for efficient recovery of gold directly from the waste mixture,” say research co-authors Daria Andreeva-Baeumler and Konstantin Novoselov, supplies scientists on the Nationwide College of Singapore.

On supporting science journalism

When you’re having fun with this text, contemplate supporting our award-winning journalism by subscribing. By buying a subscription you’re serving to to make sure the way forward for impactful tales in regards to the discoveries and concepts shaping our world at present.

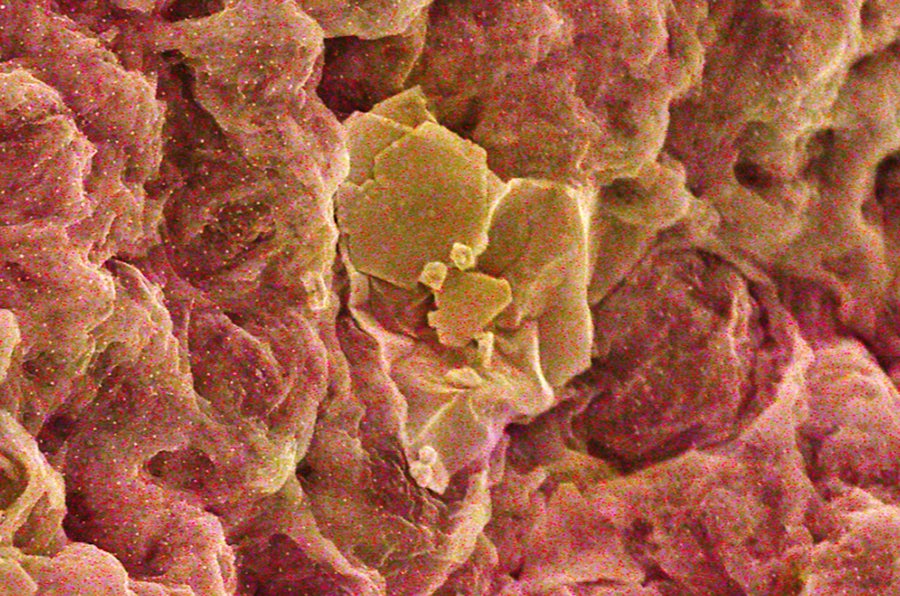

An electron microscope picture of gold particles (yellow) on the graphene-chitosan sponge.

The brand new materials is among the most potent gold adsorbers ever created. (Adsorption is much like the extra acquainted absorption, however advertsorbed issues accumulate on surfaces whereas absorbed issues are internalized. It’s the distinction between a mustard glob in your chin and the new canine you simply ate.) The sponge collected as much as 99.5 p.c of the gold by weight from liquids with gold concentrations as little as three elements per million.

“To the best of my knowledge, this is a record high value,” says Swiss Federal Institute of Expertise Zurich physicist Raffaele Mezzenga, an writer of the whey protein aerogel research, who wasn’t concerned with the analysis on the graphene-chitosan combo. He notes that as environment friendly because the sponge is, the parts wanted to make it aren’t low cost, and he questions whether or not it could be a workable possibility “under real operating conditions.” Adapting the method for industrial-scale use, Novoselov and Andreeva-Baeumler say, “is indeed the next step in our research.”